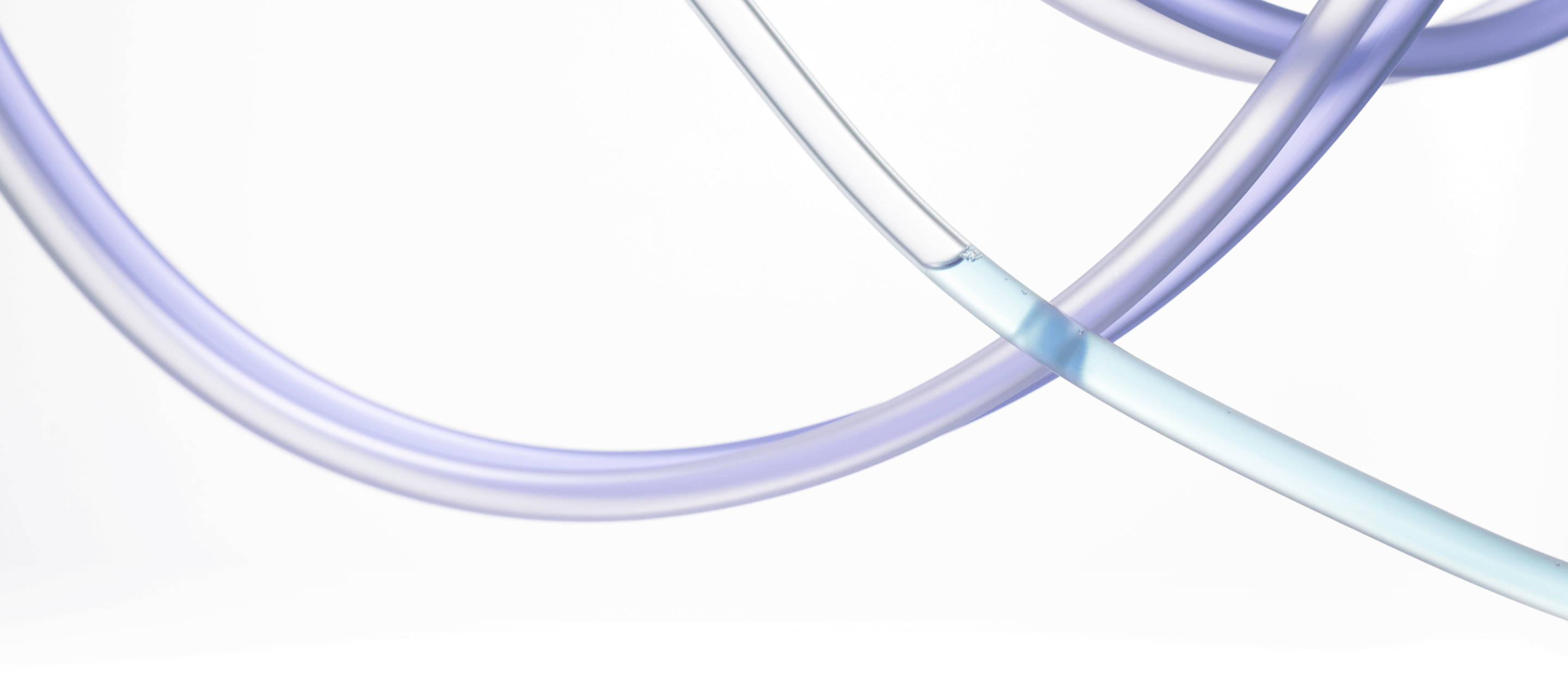

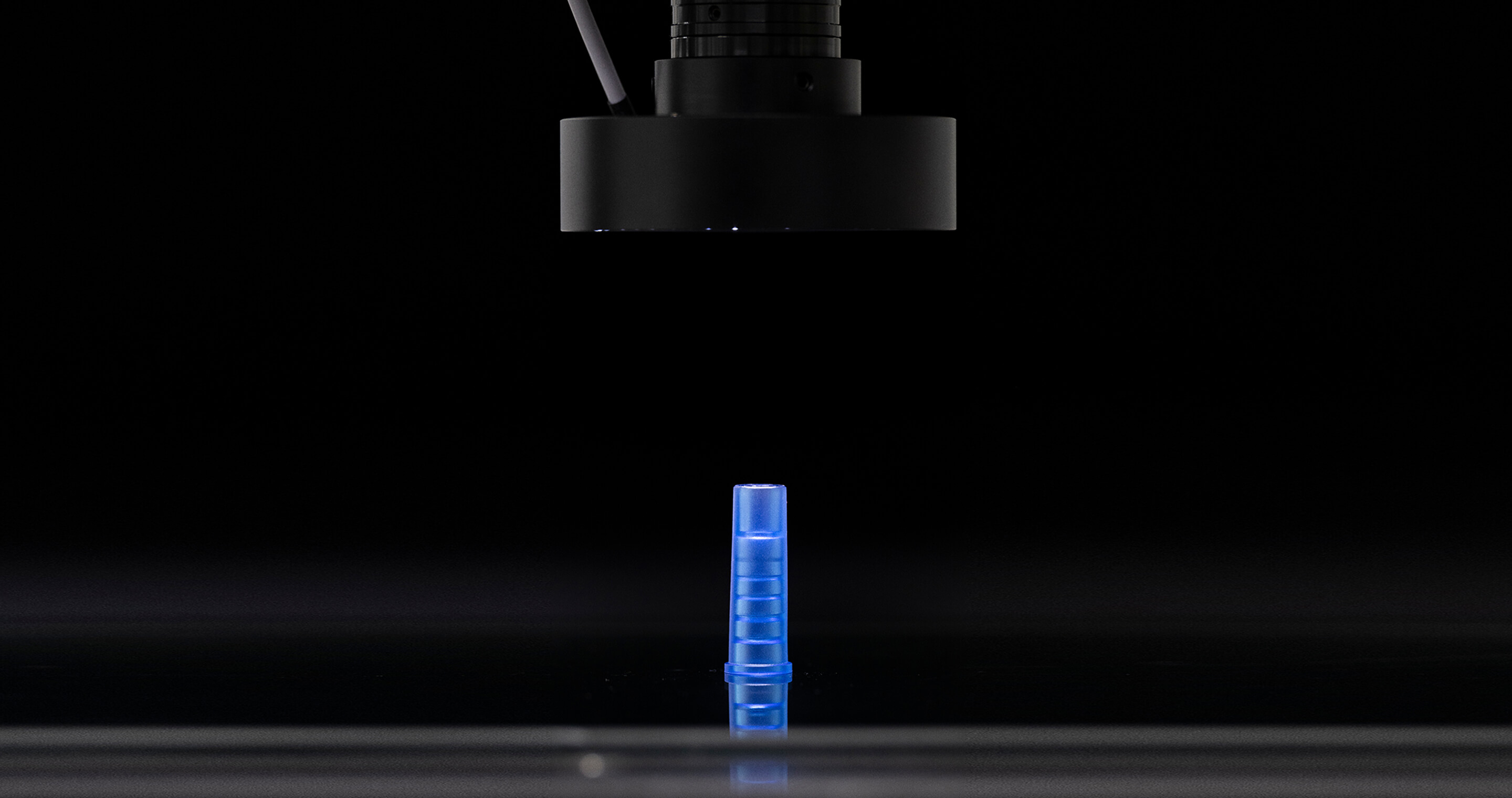

Infus is a global leader for the contract manufacturing of single use medical devices. We provide customer centric services to fulfill diversified demand of the constantly evolving medical device industry.

Infus is your

strategic partner

We are a full service contract manufacturer. Whether you’re a start up or an established industry leading company, we tailor our capabilities and services to best fit our customers’ specific needs. We are experienced with every step of the process, from concept to prototype to scale up production.

Technical Capabilities

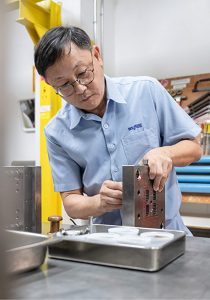

Quality

What everyone agrees on is the Infus quality.

And that is what we pride ourselves on the most.

Careers

We are looking for enthusiastic and energetic candidates to join our company

At Samutprakarn and Khon Kaen

for the following positions.

News and events

Infus Medical Returns to MedDevice Silicon Valley 2025

| Date | 19-20 November 2025 |

|---|---|

| Venue | Santa Clara Convention Center |

| Booth | 817 |

Infus Medical Empowers Employees with Life-Saving Skills

| Date | 28 May 25 |

|---|---|

| Venue | Infus Medical (Thailand) |

Events

Infus Debuts at Med-Tech Innovation Expo 2025 with Cutting-Edge Medical Device Solutions

Infus is set to showcase its latest innovations in single-use medical devices at Booth B26, NEC Birmingham, marking its exciting first appearance at the UK’s leading medtech event.

| Date | 4-5 June 2025 |

|---|---|

| Venue | NEC, Birmingham, UK |

| Booth | B26, Hall 2 |